Need Drying Trays?

The iDry&Cure way

HARVEST -> BUCK -> GREEN TRIM -> LOAD TRAYS -> DRY

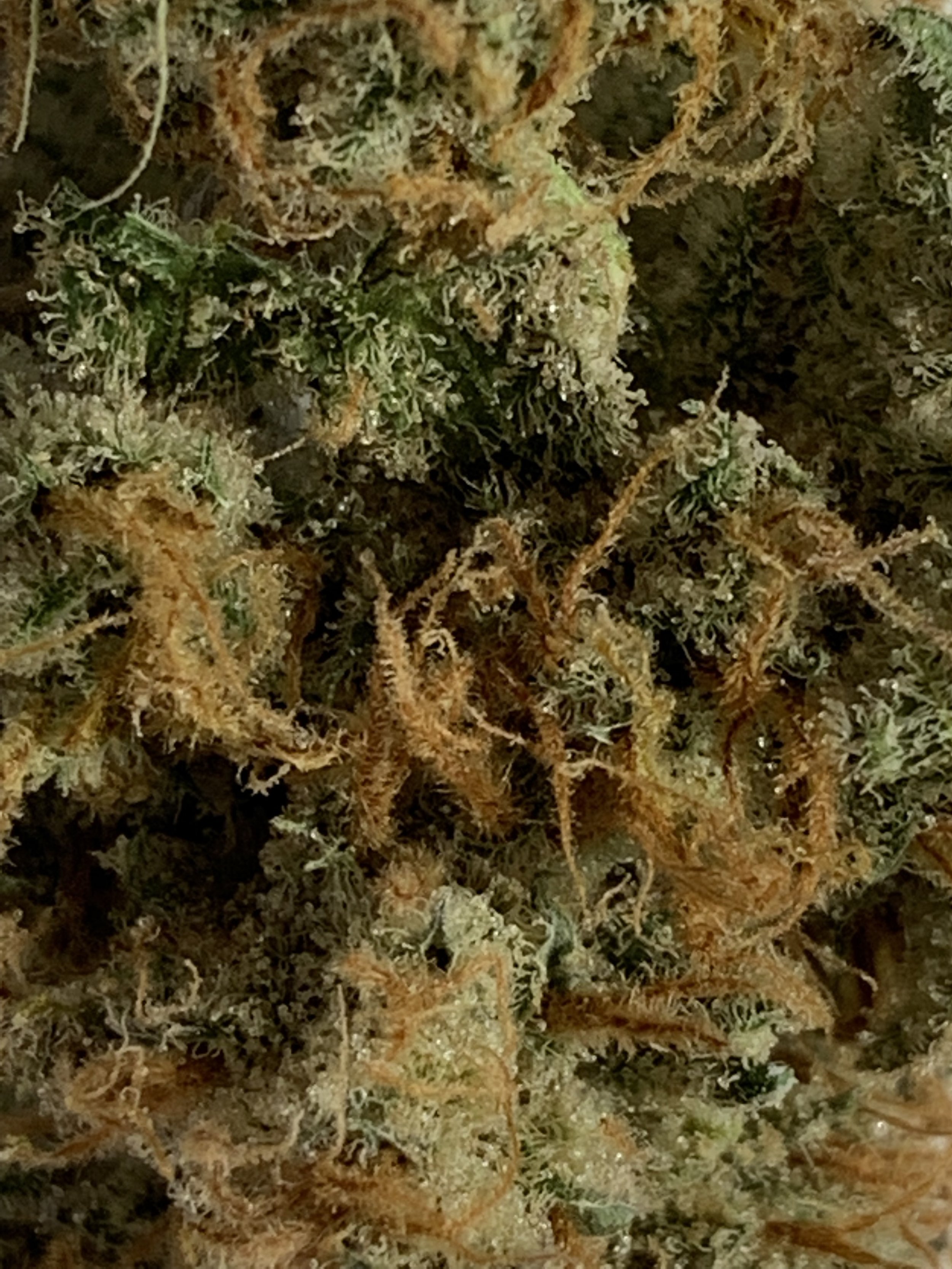

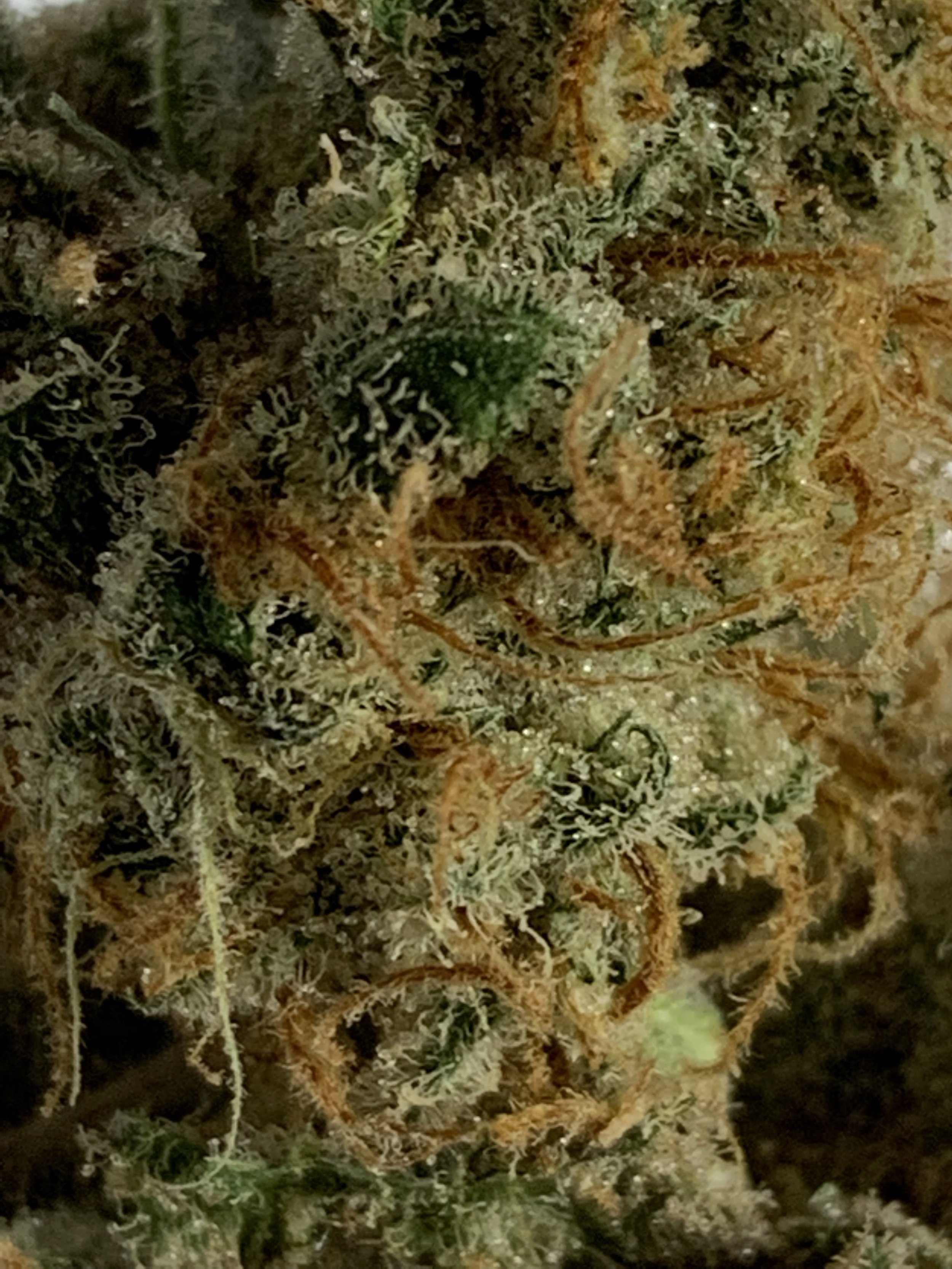

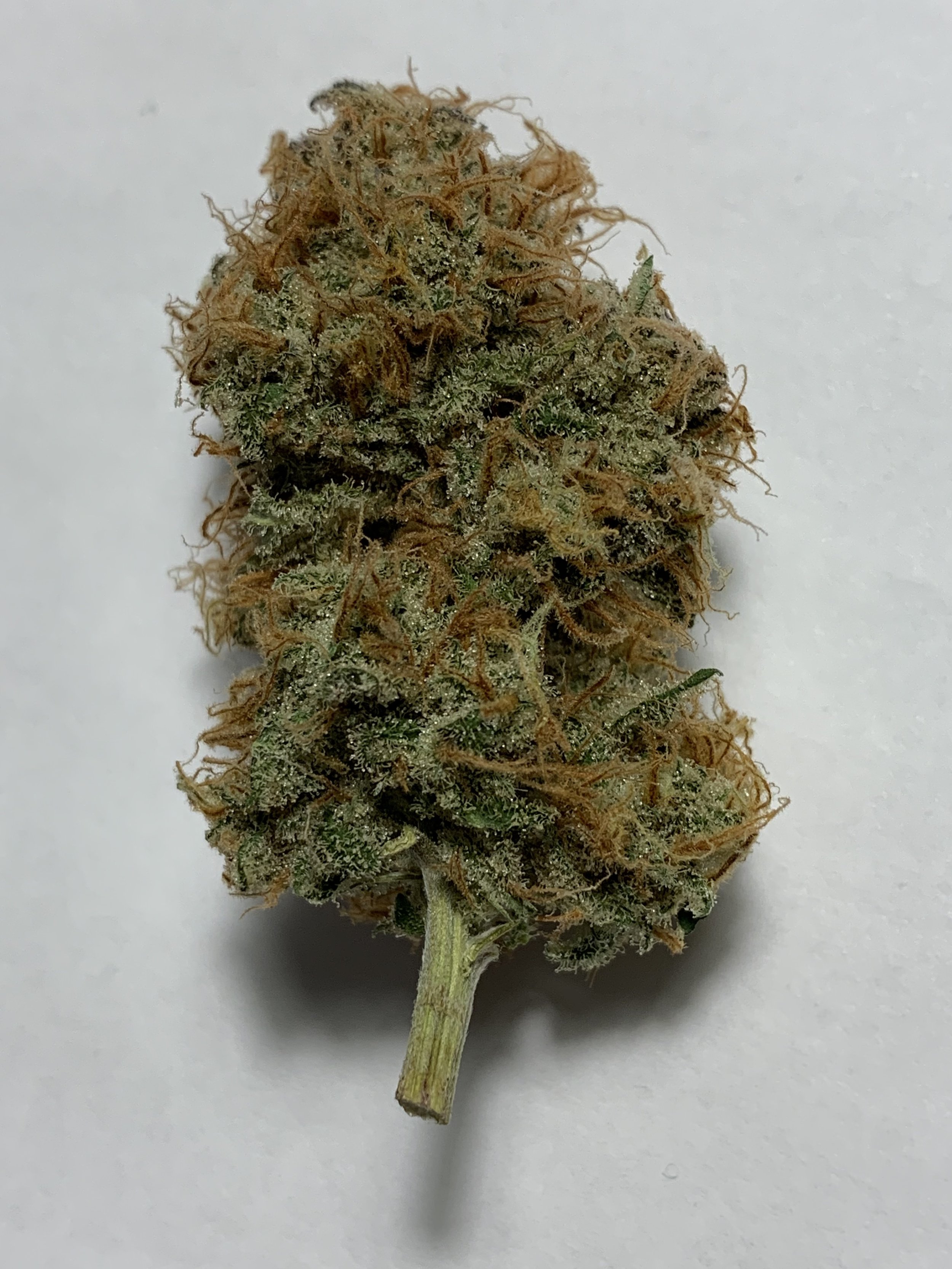

Correctly loaded trays

Loaded with bucked and green trimmed flower

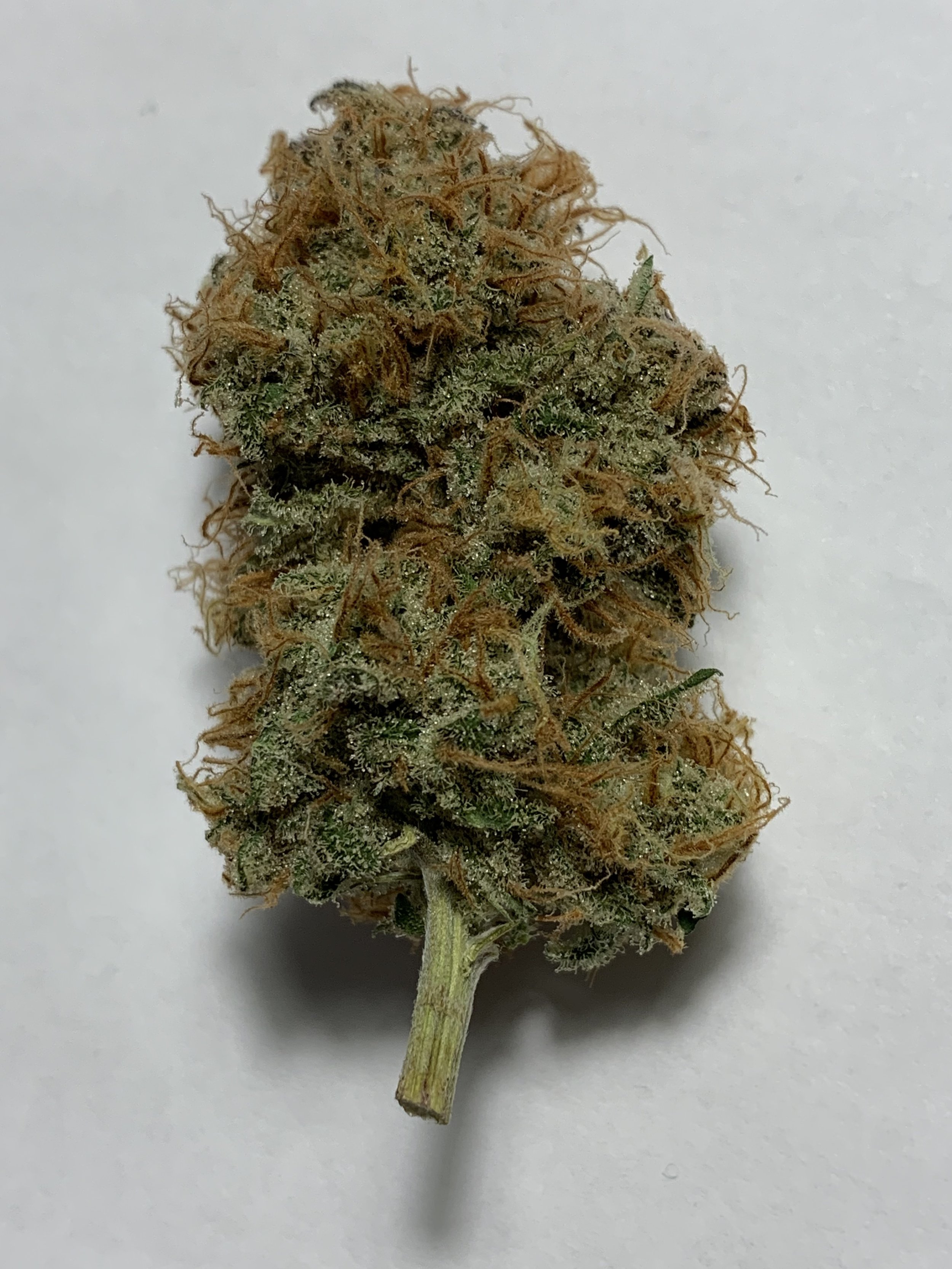

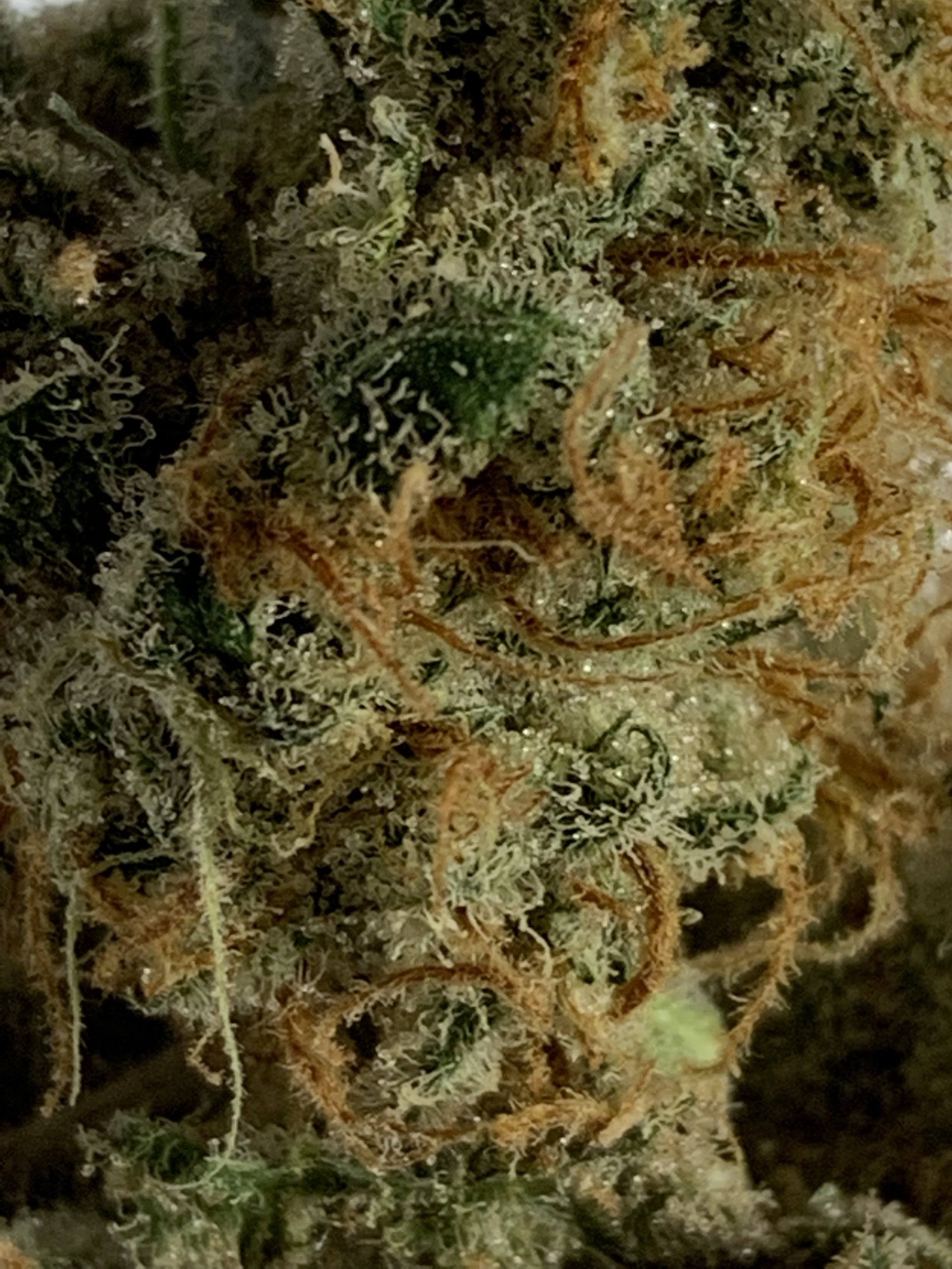

NOT LOADED CORRECTLY

We don't dry cannabis colas on stem. Buck the flower off the stem and green trim prior to drying in the iDry&Cure.

Drying cannabis flower on the stem is like drying a leaves on a tree and the log at the same time! There’s no magic in the stem, it just really dense and slows the drying process and increases risk of mold.

The large colas block the airflow too.

Buck (strip) the flower off the stem before drying.

You don’t sell colas anyway and it’s way easier to remove flowers wet.

DON’T FREEZE YOUR WEED

Freezing your hemp or cannabis crop before drying doesn't work. Don’t do it. Really.

Nice flowers make nice flowers

No need to stuff the tray full. Airflow is important in drying.

Buck and trim your flowers before drying and you will have nicely dried flowers coming out (we know it’s a lot of work, but it has to be done sometime if you’re selling a smokable flower).

Don’t dry leaves

(unless you want to only dry leaves)

Nobody wants leaves…so don’t dry them.

It takes up precious room in the trays and has no valuable weight.

Did we mention drying leaves is dumb. (unless you want to only dry leaves)

Remove branches, Buck, trim, load trays.

Skip a step and you risk, mold, slow drying, more difficult dry trimming, knocking off fragile dry trichomes.

The ONLY way to check moisture in cannabis

All of the food industry uses water activity meters as the measurement for moisture and to determine shelf stability and food safety for the FDA. You should too.

Customer Testimonials

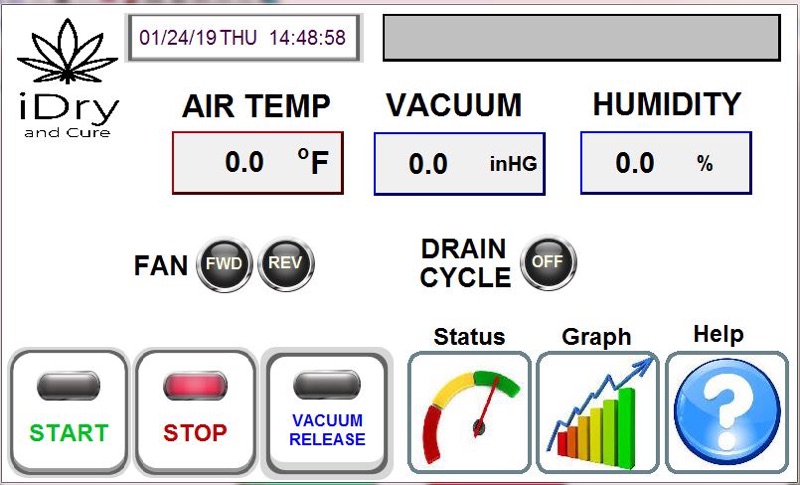

Vacuum Drying & Curing

Removing water from flowers at low temperatures in a low oxygen environment is the key to the best quality product. Doing it fast with excellent terpene and cannabinoid retention is what we care about most. Negative pressure on the flower pulls moisture gently to the surface allowing it to evaporate at the same rate from core to shell; preventing “case hardening” or “crunchy” buds that then require weeks of curing (moisture equalization).

Think of it as drying at the top of Mt. Everest. High altitude, low pressure, low oxygen creates an environment for your flower to reach its full potential.

Increased TIME exposure to heat, oxygen, physical agitation, and light all play a role in degrading terpenes. Shortening the time it takes to remove moisture evenly from the bud in low oxygen, low heat, no light and with minimal physical agitation is key in Terpene preservation. Remember, Myrcene is the terpene that helps THC to reach the brain. This sensitive little monoterpene leaves over time. Shorting the time it takes for your product to reach the consumer helps maximize the delivery of THC to that customer.

PATENT PENDING

Parallel Terpene Study

Drying and testing conducted during customer trial….they bought one.